In

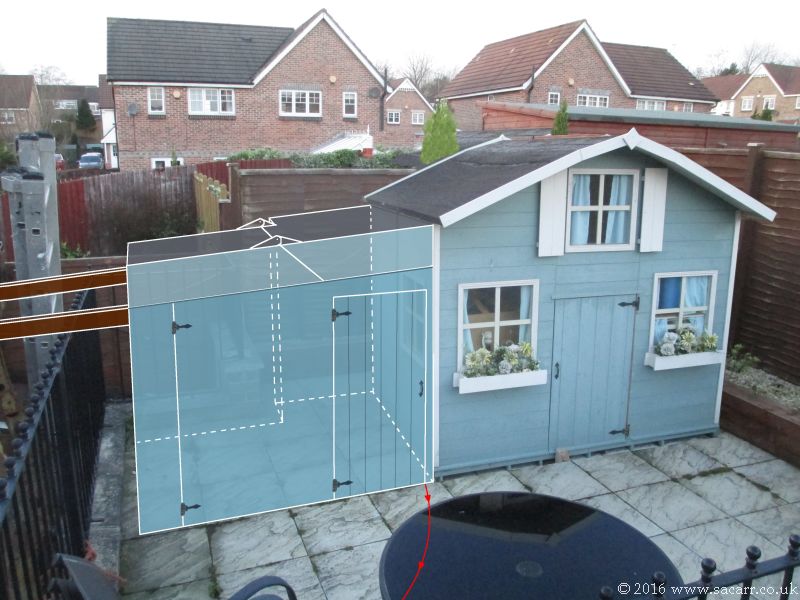

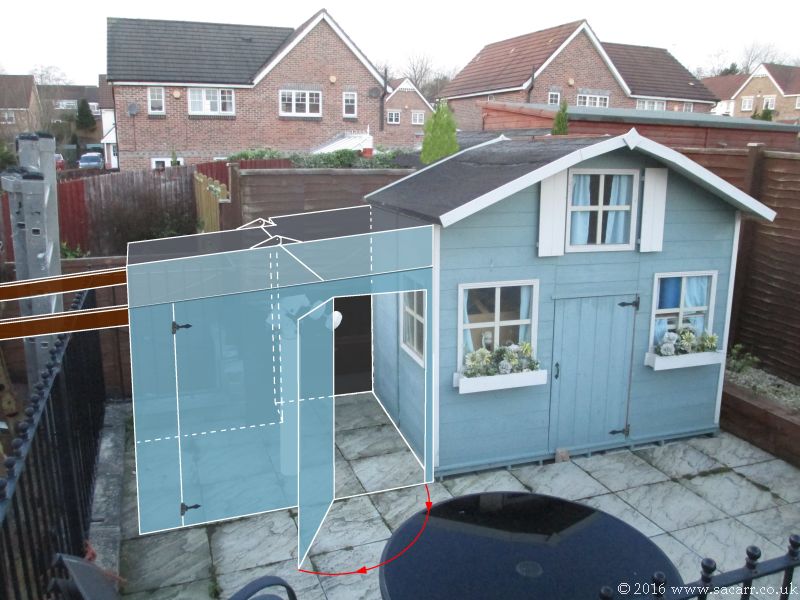

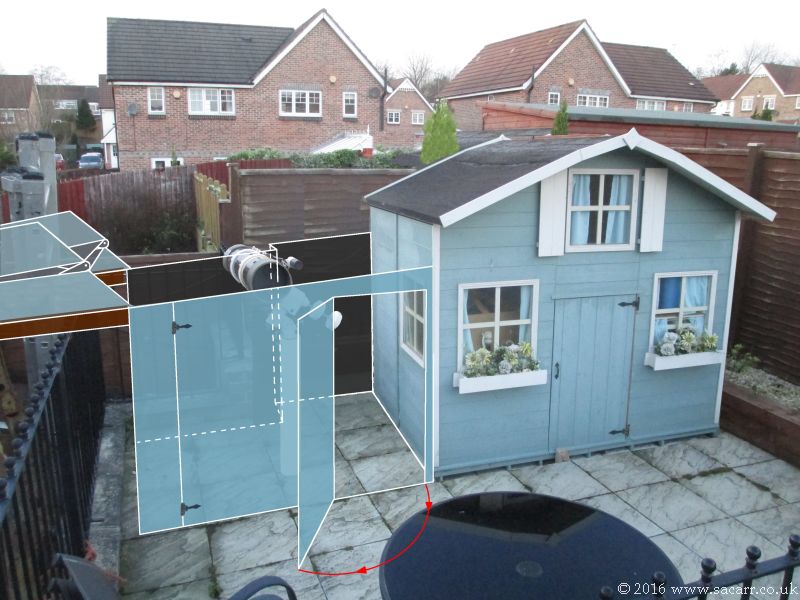

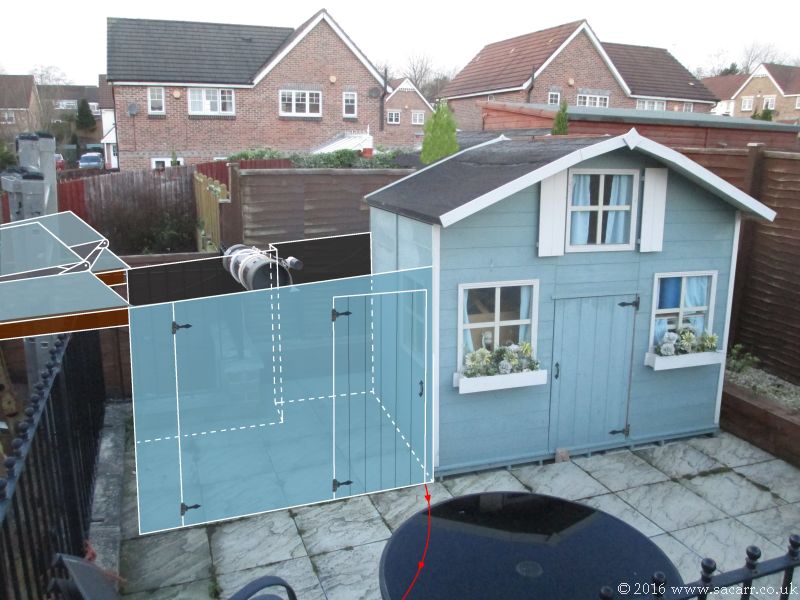

December 2015, I began to wonder if there was space for a permanent

observatory. Carrying all the equipment up two sets of steps to the

patio was a pain, but clearing it away in the freezing cold and when

tired was ever worse. With a little moving of the play house, I

would have space for a 5 x 4 feet shed on the side of the play house.

This would also mean less materials, as one wall was already built. The

images below show the planned idea, and the various configurations for

getting in and observing and imaging.

|

|

|

|

|

|

|

|

|

| Jan

9th - The

pier adapter was turned from dense modelling resin. A polar alignment

peg was made from a machine screw and some square bar welded together.

This adapter will be bolted to the steel levelling discs which will be

attached to the concrete pier. |

|

The mount adapter was drilled for the M6 bolts that attach it to the levelling plate. The top side of each hole was then recessed for a 'T' nut. The 'T' nuts will be epoxied in place eventually.

|

|

|

| Jan

12th - Next, the steel plate was drilled for the large central bolt, and the four fixing bolts. I've only got a hobby sized pillar drill, so to reduce the strain on the drill, the central hole was drilled to 6mm to start with, and then I worked up the drill sizes until the bolt fitted. The fixing bolt holes were then drilled and the bolts test

fitted. The central bolt will probably have a steel plate welded to the head, with a hole for a padlock to pass through. It can then be screwed into the mount and padlocked in place to prevent easy

removal.

The last couple of pictures

show the mount assembled onto the adapter and levelling plate. Next job will be drilling both steel discs for the levelling studding, and also for the studding that will attach the lower disc to the concrete pier.

|

|

|

|

|

Jan

21st - The

levelling plate was drilled for its bolts and the lower plate had eight

nuts welded to it to attach the bolts and the fixing bolts that would

attach the discs to the concrete pier. It was then trial assembled. It

still needs the discs sand blasting and painting.

|

|

|

|

|

With

all the parts complete, they were sand blasted and painted in some satin

black paint left over from my Jeep restoration.

|

|

|

Jan

22nd - Having worked out the minimum height the plate can be, while allowing me to tighten the central NEQ6 fixing bolt, I made the spacers to hold the plates apart. These are tubes of about 1 1/4 inches diameter, trimmed on my lathe, and they drop over the levelling plate bolts.

Of course, being an EQ mount, there's no real need for

levelling, just pointing at Polaris, so perhaps attaching plate would be more appropriate. |

| Jan

31st - The bolts clamp the attaching plate down onto these tubes, giving a nice wide and firm footprint to sit on, while leaving about 40mm of clearance for the central fixing bolt. After this picture, it was taken apart again and the parts painted.

A few days ago, the postman brought a metre long plastic tube for my pier. The tube and the pier adapter were put out on the patio for a picture in their approximate location in the observatory. Not an easy task given the wind around here over the last few days. |

|

|

Feb

8th - Today I had a hard morning of lifting and carrying! 23 off 5 metre decking planks collected from the yard where I keep my WW2 Dodge. Loaded onto the roof rack, driven home, and unloaded in through the lounge window to get a straight run through to the back garden. ( the garage is too full of Jeeps to get past through there! ).

|

|

Almost all

are very dense and heavy; there's just a couple of what feels like softwood planks

that are much lighter in weight. They can be used for internal structure in the observatory. Fortunately, the Jeep chassis on the patio is on the way out the door shortly, having found a buyer about a week ago.

The next job will be to pull out all the hammered over nails, and give the planks a wash and scrub to get the algae, dirt and flaky paint

off. |

|

| Feb

26th - The first of the planks were cut to size today, to form the

footprint of the playhouse and observatory. One or two planks had some

'shakes' along the grain, so they were first painted with dilute PVA

glue to seal the splits. After that, they were given the first of a few

coats of a bitumen paint, to seal and waterproof them. These 'footprint'

planks will be fastened down and the playhouse and observatory attached

to them to make one structure. The gap will allow a little airflow below

to reduce damp. |

|

|

|

Feb

28th - The next step in the build was to clean the patio, prior to

moving the play house. All around the front and sides was jet washed,

leaving the patio flooded in about an inch of water. Two paving slabs

were lifted to help the water drain faster. Once the water was gone, the

patio was swept of weeds and dirt left by the water. |

|

|

Feb

29th - The following day, the play house was jacked up on some scraps of

wood to reduce friction on the ground. The first of the bitumen painted

foundation planks was fitted across the patio, just in front of the play

house, and then I was ready for the move. I fitted straps around the

play house, and attached a ratchet winch to the straps and to a fence

post. |

|

|

Slowly

the tension was increased until the house moved forwards, and at the

same time, it was shoved to the right, close to the sleepers around the

edge of the patio.

The front edge of the play

house was lined up with the decking plank, while the back of the house

was lifted a bit higher. This allowed the fitting of the rear and centre

decking planks that support the play house floor joists. |

| With

all the supporting planks fitted, the wooden blocks were removed, and

the play house lowered onto the foundations. Two more paving slabs were

lifted around the pier position and the bedding sand cleared away. Below

the sand was the weed barrier, and this was then cut and folded back out

of the way, revealing the packed hardcore below. This will take some

effort to dig out. |

|

|

| Mar

2nd - Further investigation of the play house revealed that the

chipboard floor was actually rotten. I decided that the best option was

to replace the whole floor. I cut six of the long decking planks into

twelve, seven feet long planks for a new floor. They were painted with

more bitumen paint on the bottom face and left to dry overnight. While

they were drying, out came the mini pick axe, and I started work on the

pier foundation. |

|

|

|

|

| Mar

3rd - With the decking and some support strips dry, I began to assemble

the new floor. It is substantially heavier and stronger than the

original floor. Fitting it was the next challenge. I screwed two further

decking planks, one to each side of the house, to form long levers.

After the old floor was unscrewed from the walls, the long planks were

used to lift the house up and clear of the floor. That was pulled out

and the new floor lifted into position, followed by screwing the walls

down to the new floor.

Once the floor was sorted, I

moved on to the observatory roof runners. I needed to know the height of

the roof in order to work out the height of the telescope and also the

pier, so it would clear the roof as it was opened. Two more decking

planks form the support for what will be an aluminium channel. |

|

|

|

|

| Mar

4th - On the 4th, I fitted a dummy mount and telescope to the skeletal

pier structure to calculate the pier height.

|

|

The

reinforcing bars were pushed into the bottom of the hole until the dummy

telescope cleared the position of the roof. That gave me the height of

the pier tube which was cut to length. The plastic tube was then jigged

up to hold it vertically.

|

|

|

|

| Mar

5th - After a little more clearing out the bottom of the hole, I had a

trip to B&Q for concrete and started mixing. I filled the pier

foundation and then left it a little while to start to cure and harden a

bit. I then used the clay/gravel spoil from the hole to cover over the

concrete to protect it from the cold and to stop the pier concrete from

slumping down the tube and out of the bottom. Once the pier was filled,

it was all left overnight.

Mar 7th - the spoil was

cleared and levelled and then the weed barrier was folded back into

place. A layer of sand was spread out as a bed for the paving slabs, and

the area around the pier was filled with concrete and we all signed it.

After it hardened a little, it was covered up with some old blankets as

frost was expected that night. |

|

|

|

|

|

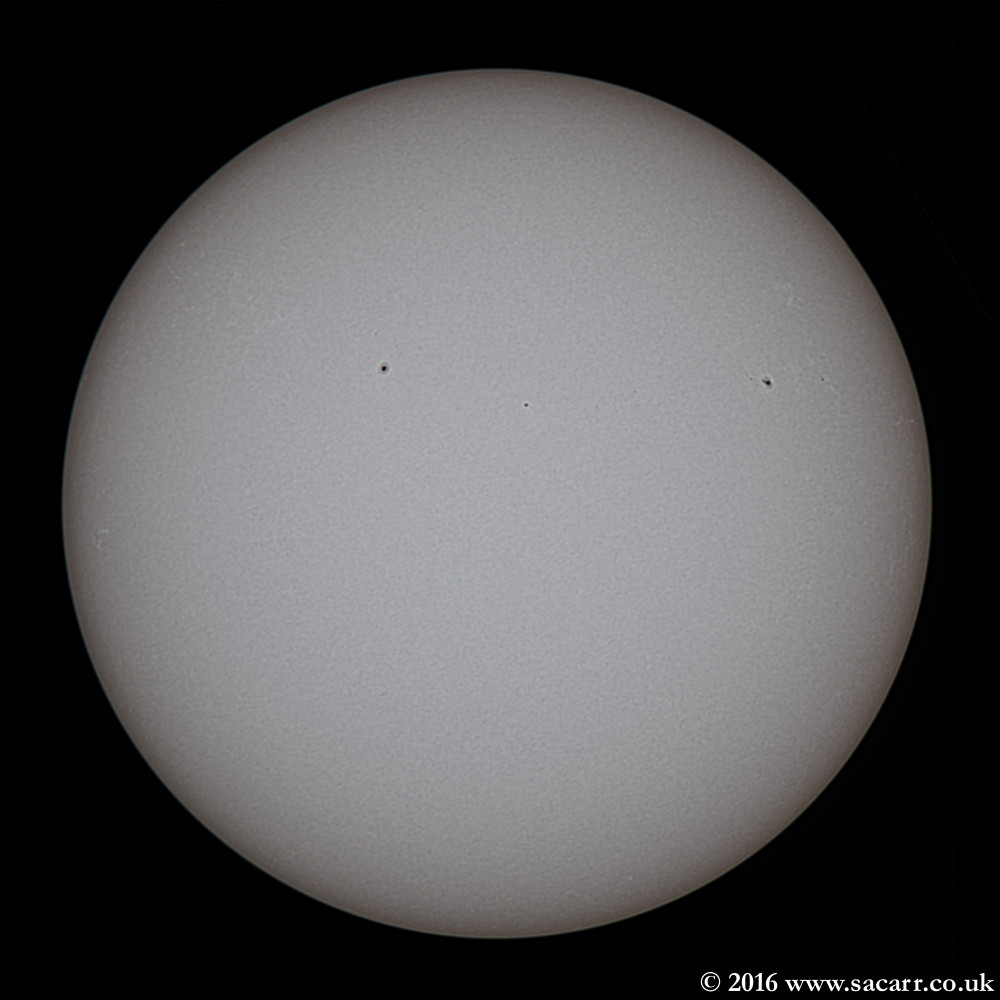

Late

in the day, the mount and 8 inch tube rings were fitted to the pier to

check the roof would actually clear the scope. Thankfully, my

measurements worked out and it was clear. The 8 inch tube rings were

then removed, and the Evo 80ED was fitted for a quick solar shot, and

while the mount wasn't powered at the time, it was first light for a

scope on the pier. |

|

|

| Mar

10th - After a jig was made for my circular saw, I was able to cut the

decking planks down the middle. These smaller timbers were used to frame

up the basic structure of the observatory. By the end of the day, most

of the structure was complete. |

|

|

| Mar

11th - The framework was covered in a moisture barrier, stapled in

place. For most of the observatory, the cladding would be attached

directly over the barrier. On the door section, the framework was

skinned in plywood to give additional strength to support the large

hanging weight. Several of the low planks were pre-painted, as access

was restricted. |

|

|

|

|

| Mar

12th - Cladding continued around the back of the observatory, but after

a test fitting of the 200PDS scope, it was found to be catching the roof

runner at some low angles to the East. A box was built on the rear wall

to increase clearance space. The workshop side of the obsy was fully

clad and most of the main door was clad. |

|

|

|

|

| Mar

13th - The cladding was completed on the large door, which was then

hung, followed by cladding the remaining strip of wall up the right side

of the front wall. Late in the day, I took a few Moon shots from the

scope on the pier. The mount wasn't powered at the time. |

|

|

|

|

|

Mar

14th - The frame of the small door was built into the hole in the front

wall, with some temporary diagonal bracing to hold it square when

removed. Six cladding planks were glued together, slightly over sized,

and the frame was glued and nailed to the cladding. Once dry, it was

trimmed, painted and hung. The roof runner supports were also painted

and properly attached to the workshop wall. Another clear sky allowed

the chance to power up the mount and image the Sun and Moon properly for

the first time. The following day, the roof hinges were made. |

|

|

|

|

|

| Mar

16th - I had a few interruptions but got the basic frame for the lower

roof made and test fitted on the obsy to check a few things. |

|

Mar

17th - I made the trip to Metal Supermarkets to collect the aluminium

channel for the roof runners. After cutting and fitting the channels,

the wheels were fitted to the frame of the lower roof and it was test

fitted and rolled down the tracks.

|

|

|

Mar

18th - The frame for the lower roof was completed and the plywood top

was added. I also started the frames for the upper roof section. |

|

Mar

19th - Both roof sections were trial fitted in the closed and open

positions. This gave me the chance to check whether it had any impact on

the South views. |

|

|

|

|

| After

the testing, the ply top was added to the upper roof, and that was left

to dry. I then returned to the lower roof and started attaching the

cladding. It was a slow process requiring lots of nails, screws and

clamps to attach the slightly warped planks. Several were run under a

hot tap to soften them prior to fitting. Last job of the day was to glue

on the cotton with dilute waterproof PVA glue. This was the first layer

in waterproofing the roof. |

|

|

| Mar

20th - The roof sections were clamped together and the hinges were trial

fitted first thing. This required a spacer either side of one roof

section to allow the hinge plates to overlap. |

|

|

The

cladding was then painted in green, and a number of areas around the

runners were waterproofed and painted, as they would not be accessible

once fitted. The waterproofing overlapping lip between the roof joints

was also made and cotton covered. |

|

While

that was drying, I made the roof for the storage area of the observatory

using some left over cladding. The last job for the 20th was to give

both roof panels two coats of gloss grey paint. |

|

|

| Mar

21st - I gloss painted the two small roof sections early in the day, to

give them plenty of time in the sun to dry. The next big job was to fit

the roof panels, starting with the lower roof section. The wheels on one

side were dropped into the channels, and it was lowered into position.

The other wheels were then slotted into the channel under the edge of

the roof and screwed in place. The second roof panel was then fitted,

but at this point, the whole roof was now trapped and while it could

slide, it couldn't lift. |

|

|

|

To

allow the upper roof to lift and fold, I needed to cut slots into the

top of the runners to allow the wheels to lift up and out. I slid the

roof sections to a convenient position for opening. I also made sure the

slots wouldn't fall in any of the wheels parked positions when the roof

was closed. They were marked and then the slots hack-sawed out and the

slots cleaned up with a file. The next three pictures show the slot and

the wheels lifting clear. |

|

|

|

With

the slots cut, the upper part of the roof was clear to lift out of the

runners and fold over on top of the other roof. With it open and pushed

right down the track, the roof is below the roof line of the house, and

so shouldn't interfere with the views. |

|

| To

hold the roof closed, I drilled the play house end wall and fitted two

M12 bolts for the roof to slide over. Nuts would then clamp the roof

closed against the wall. At the end of the day, the observatory was

looking quite complete. |

|

|

|

| Mar

23rd - With the play house consuming a large number of the decking

planks, I as beginning to wonder if there would be enough left for the

observatory floor. As it happens, there was, but only just! The floor

planks were cut and trimmed to fit around the pier. As yet, they haven't

been painted, but need the undersides painting in bitumen paint, and

perhaps the upper surface in anti-slip paint. |

|

|

|

|

The

mains power was re-routed from the play house to the observatory, though

only in a temporary location. I'll need to wire in sockets and some

lighting, but their final position hasn't decided.

The rubber seals were also

fitted to the roof sections. They sit in slight slots in the ply and are

superglued in place. |

| Mar

24th - I did some artificial rain testing with the hose today. Overall,

the observatory performed quite well. A couple of cladding planks were

leaking at a joint on the small extension, but that's easy enough to

seal. At certain angles with the hose driving water into the centre roof

joint, it was leaking a little, so I have a few little tweaks to do to

that, but in general, the leak test was fairly successful. |

|

|

| Mar

25th - I was out with the family in the morning, but later in the

afternoon, I got back to work. No pictures, but the time was spent

making a new overlapping joint for the roof join. By the end of the day,

it was fitted, and partly covered in fabric. |

|

Mar

26th - The rest of the new roof joint was covered in fabric, but the

forecast wasn't great for the day, with heavy rain arriving later. The

roof seal once done, was covered in plastic to protect the glue while it

cured. In the mean time, I started some work inside. The wall on the

workshop side, and part to the right, was skinned in left over 1/2 inch

ply wood. This gave me a nice firm wall to attach the electrical

junction box and four gang socket. |

|

| Mar

27th & 28th - The observatory was painted another couple of coats

all round and the big door hinges painted over. The roof seal was also

reworked as at certain angles of simulated rain, there was a slight

leak. Inside, the adjoining window was removed and for security, a

wooden panel was fitted with a small 'Mission Control' window for

monitoring during deep sky imaging. The flooring was also painted with

bitumen paint on the underside, and left to bake in the observatory with

a heater on. The white trim was also painted along the roof line to

match the play house when they are refitted. |

|

|

|

|

|

|

| On

the evening of the 28th, it was partially clear, so I fitted the 200PDS

for some Jupiter imaging. Thin cloud and patches of thicker cloud

spoiled the views, but I did manage some reasonable close ups and one

shot with all the moons strung out to one side of Jupiter with the GRS

showing. |

|

|

|

|

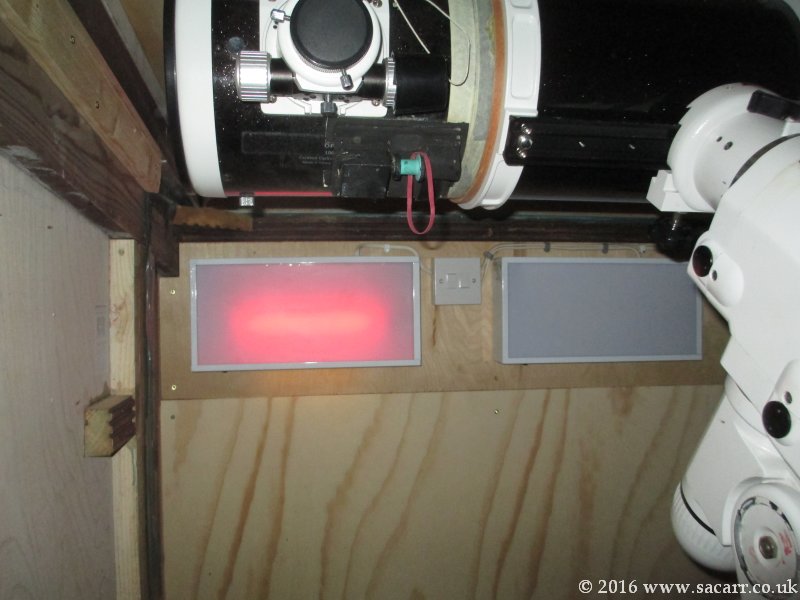

Mar

29th - I painted the removed window frames the day before so that on the

29th, they could be fitted. They were glued and screwed to the large

door, and then the gaps in the cladding planks were filled. Once dry and

sanded, the window was painted a gloss dark grey and left to dry. To aid

opening and closing the roof when the large scope was fitted, I made a

multi-function stick that was a hook and a lever. This lever hugely

reduces the effort in folding the roof sections. Red and white lights

were also fitted to the wall, together with a dual switch. The white

will double as a flat field panel. |

|

|

|

|

|

| Externally,

the observatory was done with the fitting of the small cross bars in the

window, however, there were still some small jobs to be done inside.

Mar 30th - The floor needed

some additional joists before being screwed down, so they were cut and

painted. I used some flat rubber strips to act as shock absorbers under

them. The gaps in the floor around the pier were covered. The Goto

handset was attached to the pier with Velcro and I started moving astro

kit inside! |

|

|

|

|

|

|

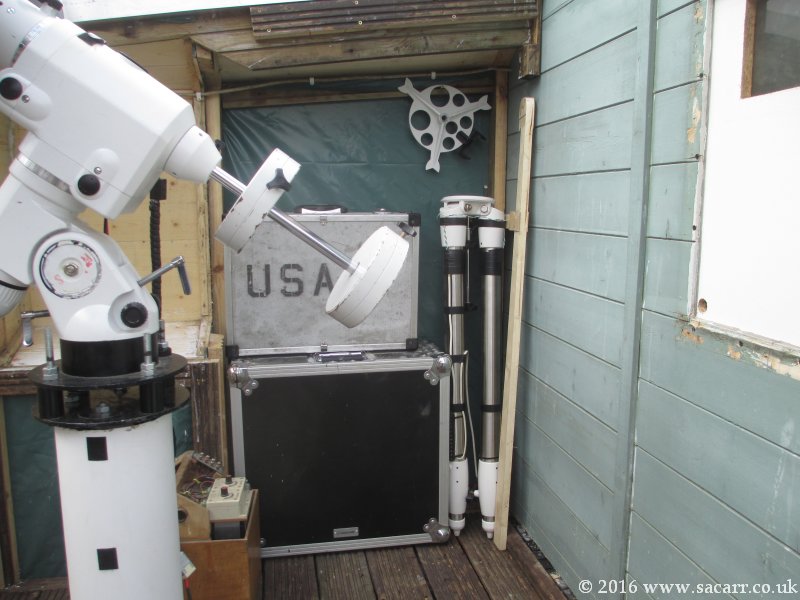

| The

flight case for the NEQ6 and the case for the ancient guiding laptop

fitted in the storage alcove, along with the tripod and roof stick. The

wooden box that shades the laptop when solar imaging was flatpacked and

hung from the wall in the far left corner. Near to the large door, I

hung the bahtinov mask and solar filter.

|

|

|

I

also made a small 'catflap' in the play house wall so I could pass the

Goto handset through into the warm room for when I'm deep sky imaging.

So other than a few touch ups

and painting the play house, it's done!

|

|